- Deformation Analysis is determination of geometrical changes of an object due to its use or external factors.

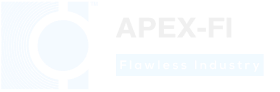

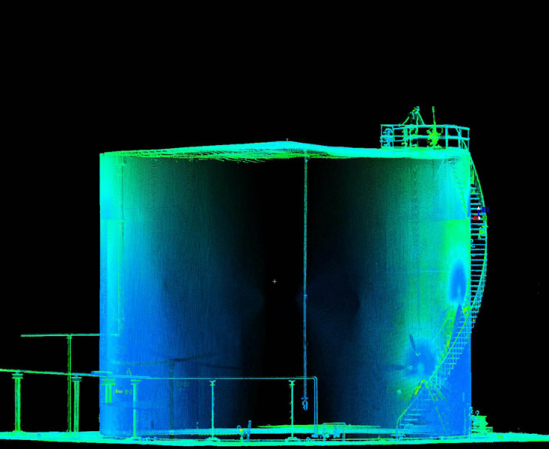

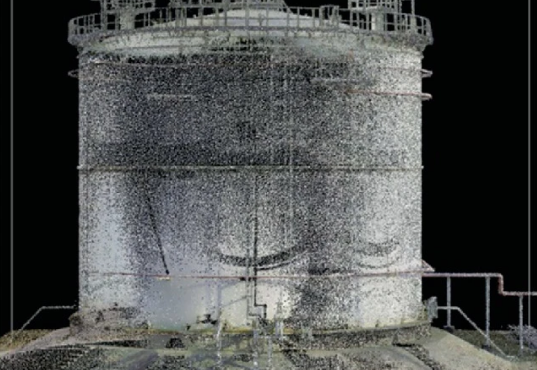

- For large storage tanks, 3D laser scanners capture accurate geometry information that can be used to analyze the true shape and any deformation of the tank structures. Older measurement techniques required multiple measurements and a lot of time. 3D scanning of tanks makes this process faster and more accurate millions of measurement points in a single scanning session.

- APEX-FI uses high end, precise 3D laser scanning systems to gather the as-built data of the object and use this data in the analysis of the deformation of the object. Provide highly detailed reports showing the magnitude and the location of the deformation.

- 3D laser scanners can capture very accurate measurement information in a short period of time. Captured data is then analyzed either in the office or on a mobile computer to provide:

- Height and diameter measurements

- Angle or tilt information

- Area/volume measurements

- As-built 3D models of the tank structure, footing and equipment

- Shape information, such as tank roundness

- Deformation, or change, in objects over time

- Many of these measurements from 3D scanners can be used to provide additional information for tank applications, such as:

- Inspection

- Design/modification projects

- Deformation monitoring

- Containment dike analysis

- Volume calibration