Traditional Techniques

Vacuum box testing is an effective leak testing technique used to inspect welding joints. This is a relatively fast test and one that can be conducted without interfering with other…

A holiday test is an inspection method used to detect discontinuities in painted/coated surfaces using specialized tools and equipment. These tools, called holiday detectors, are portable devices that are swept…

Many things contribute to a quality painting, coating or lining project. When quality control is mentioned in regard to an industrial coating application, people tend to focus in on the…

The EMAT is an ultrasonic transducer, which operates without the application of liquid couplant. The EMAT transducer generates the ultrasound in the material being tested. As with piezo electric transducers,…

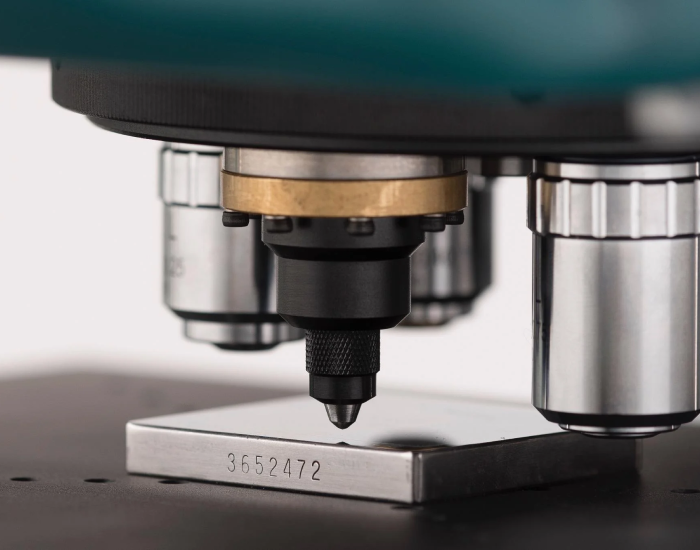

Hardness testing makes it possible to determine material characteristics such as strength, ductility and wear resistance. It also shows whether the heat treatment process has been carried out properly. These…

PMI Positive Material Identification : Advanced NDT Solutions personnel have extensive experience in PMI Positive Material Identification. Our experienced Inspection Engineers are certified to ASME and EN non destructive testing…

Industrial Radiographic Testing (RT) makes use of X-ray or gamma radiation to create images that can show defects hidden inside the material. This technology is widely used to ascertain material…

Ultrasonic Testing is a volumetric Non-Destructive Testing (NDT) method. Unlike surface inspection methods, UT makes it possible to find flaws inside the material. Highfrequency sound waves are sent into the…

Magnetic particle inspection (MT) is a non-destructive testing method used to detect surface and slightly subsurface flaws in ferromagnetic materials (such as carbon steel). It is used routinely to inspect…

Dye Penetrant Testing (PT) is used to find surface breaking defects. PT inspection is suitable for a wide variety of materials, but it is mainly used on non-ferrous metals. This…

Visual Testing (VT) is based on the inspection for flaws that are visible to the naked eye and is the most commonly used NDT method across all industries. It allows…