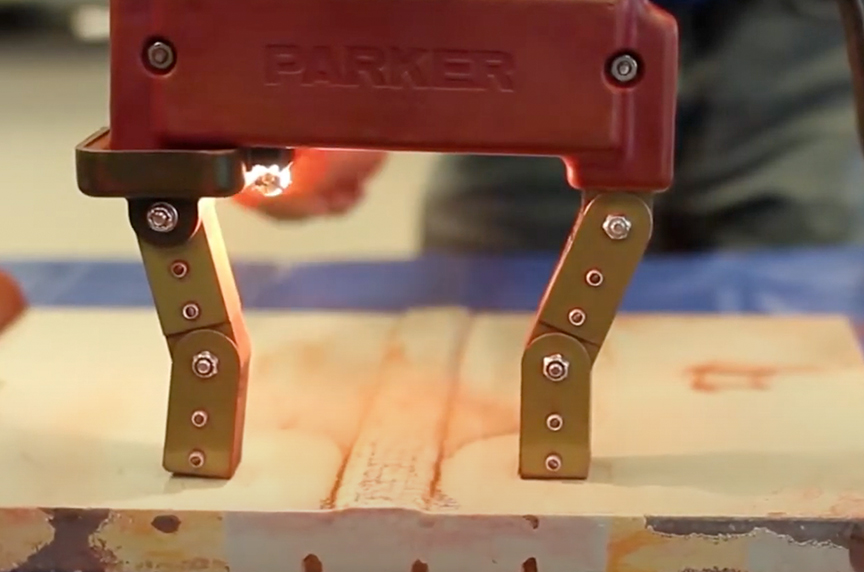

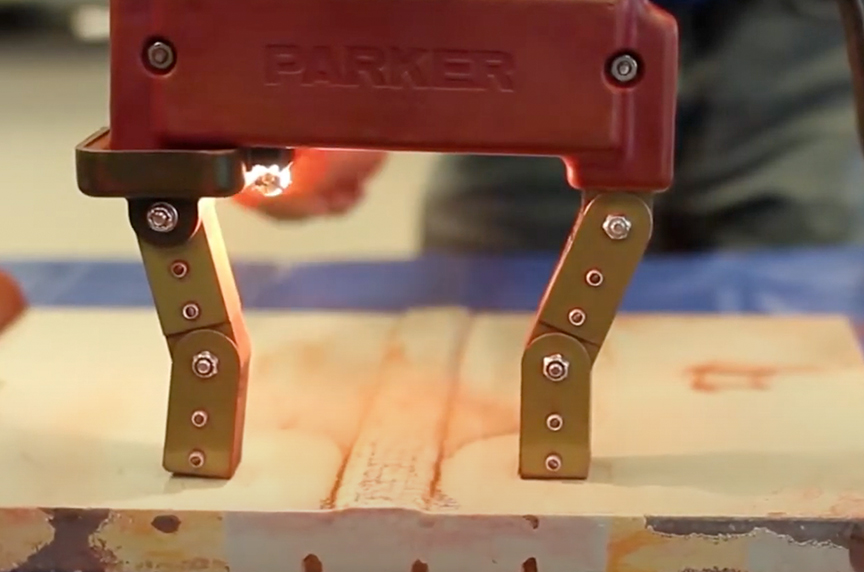

- Magnetic particle inspection (MT) is a non-destructive testing method used to detect surface and slightly subsurface flaws in ferromagnetic materials (such as carbon steel). It is used routinely to inspect welds, piping, pressure vessels and structural steel components.

ADVANTAGES

- 1. Flaws are highly visible

- 2. The equipment is:

- Portable and can be battery powered

- Light enough to take easily onto scaffolding

- Non-hazardous to operations or other nearby personnel

- Has no effect on equipment or materials in the vicinity

- Very good sensitivity to fatigue cracking, tight fusion, HIC and SCC

LIMITATIONS

- Surface must be accessible and must be clean and free from oil, grease, scale, etc

- Cannot detect deep subsurface flaws

- Instrumentation and aircraft components require demagnetization after being inspected; residual magnetization may cause them to malfunction

- May require a power supply that is not intrinsically safe