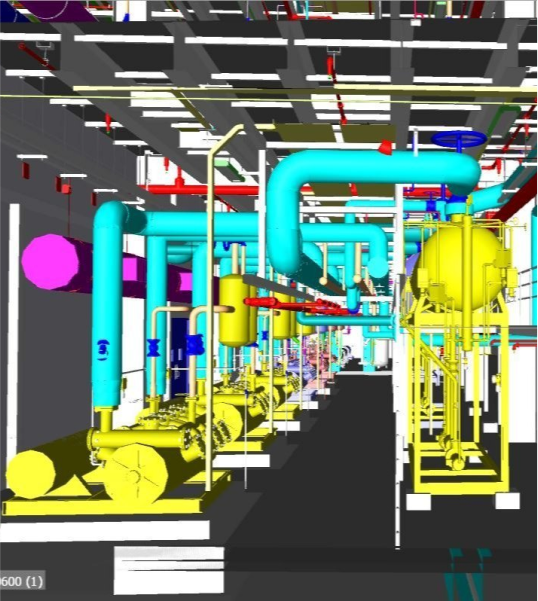

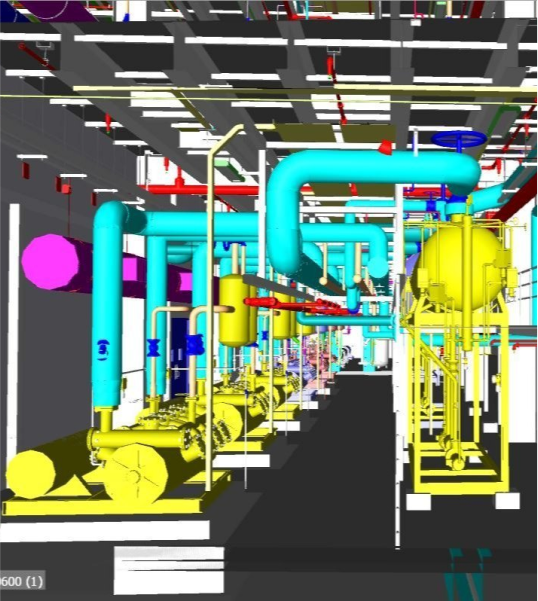

- Plant modeling is the process of creating a digital replica of every process, piece of equipment, and workflow within a plant. Process manufacturing plants are already fully equipped with sensors which gather data from every inch of the system; with plant modeling, engineers draw on that data to build an accurate representation of everything that takes place within the system and constantly update it in real-time.

We provide the following activities as part of the As Built & 3D Modeling

- Data Gathering and classification of all existing engineering documents and Drawings.

- Defining Engineering Documentation Gaps, Missing Information, and Project Planning.

- Site Survey Verification includes but not limited to:

- Process Data, Control loop and Set-Points

- Type of Fluids in Nameplates against Data Sheets.

- Changes of Nozzles, Piping Routing, and Reallocation of Equipment.

- Duty, Sparing, in maintenance and out of services Equipment.

- Updating As-built PFDs, PIDs, Equipment List, Line List, and Piping Specs.

- Intelligent 3D Modelling for Plant Units, Equipment, Piping, Electrical, Instrumentation, Steel Structures, and Supporting elements limited to the availability of design specifications.

- Extracting updated Layouts, and Drawings including but not limited to General Arrangements, and Isometrics.